Molybdate inhibited solutions are a crucial aspect of industrial chemistry that ensures the longevity and efficiency of systems in various sectors. By incorporating molybdate inhibitors, industries can protect their infrastructure against corrosion, improve system efficiency, and ultimately, ensure operational integrity over longer periods. This feature explores the mechanism of molybdate inhibition, its applications, and the benefits it brings to industrial operations.

Table of Contents

The Mechanism Behind Molybdate Inhibition

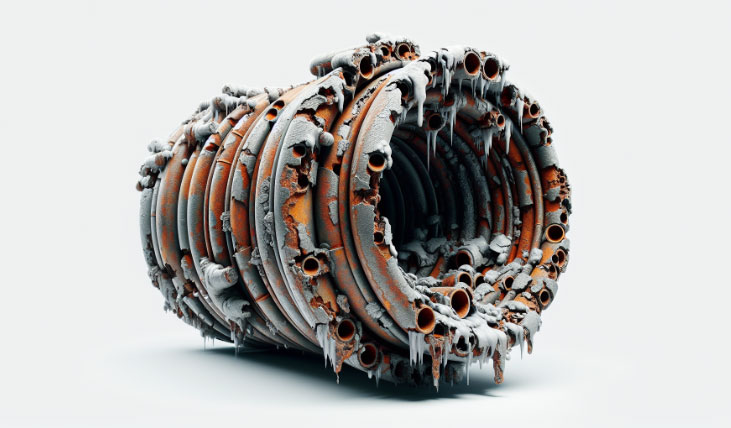

Molybdate inhibitors work on the principle of passivation, where a protective layer forms on the surface of metals, preventing corrosive substances from causing deterioration. The molybdate ions form a thin, yet strong, protective oxide layer on metal surfaces, which acts as a shield against corrosion. This is especially vital in systems where water contact is unavoidable, making them prone to rust and other forms of corrosion.

Key Applications in Industry

Cooling Systems Protection

In cooling towers and systems, where water acts as a primary coolant, the risk of corrosion is heightened. Molybdate inhibited solutions ensure these systems remain corrosion-free, maintaining thermal efficiency and reducing the frequency of maintenance operations.

Enhancing Absorption Refrigeration Systems

Absorption refrigeration systems benefit significantly from molybdate inhibited solutions. The addition of molybdate helps in protecting the internal components from corrosion, especially in the chillers, thus ensuring consistent performance and extended lifespan of the equipment.

Boiler Water Treatment

Boiler systems are another critical area where molybdate inhibited solutions prove invaluable. They safeguard the boiler parts from scaling and corrosion, ensuring optimal heat transfer and efficiency, crucial for industrial operations relying on steam generation.

Advantages of Using Molybdate Inhibited Solutions

Longevity and Durability: By preventing corrosion, these solutions extend the lifespan of industrial equipment, saving substantial costs over time.

Operational Efficiency: Maintenance downtimes are considerably reduced, leading to uninterrupted operations and enhanced productivity.

Environmental Consideration: Molybdate inhibitors are often preferred for their lower environmental impact compared to traditional inhibitors, aligning with green industry practices.

In Summary

The use of molybdate inhibited solutions in industrial contexts is a testament to their value in preserving infrastructure, optimizing operations, and contributing to environmental sustainability. As pioneers in the supply of superior quality molybdate inhibited solutions, we are committed to delivering products that not only meet but exceed industry standards, ensuring your operations are safeguarded against corrosion.

Contact Us

Leverage the benefits of our molybdate inhibited solutions to protect and enhance your industrial applications. Contact us to discover how Shandong Hongrui Co. tailored solutions can contribute to the efficiency and longevity of your operations. Embrace the future of industrial maintenance and preservation with our advanced solutions.